MANUFACTURE

design

ZAQQ barefoot shoes are simply the most beautiful way to walk barefoot. Our aim is to skilfully showcase the extraordinary, unique properties of our ZAQQ barefoot shoes through an outstanding and innovative design.

We know that design plays a crucial role, because the feeling of well-being begins in your head, long before your feet feel the soft leather and the luxury of freedom of movement for the first time.

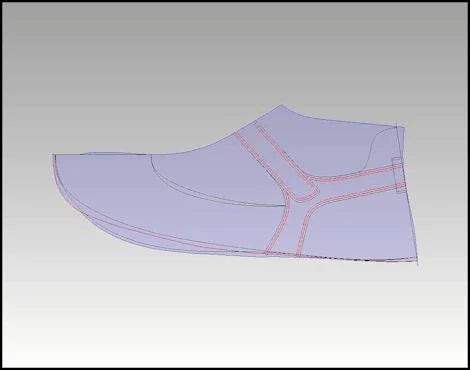

Our outstanding and simple design plays with the lightness of modern life. Double seams enclose the best possible materials in a stylish and absolutely accurate manner. The exposed strobel seam inside the shoe allows a view of the perfect craftsmanship and at the same time serves as a moving, stylish contrast to the smooth leather side of your ZAQQ barefoot shoe, because we are not satisfied with superficialities, our design goes beyond the design of the inner shoe right up to the sole.

Inside is the same as outside, outside is the same as inside. By using the finest suede, barrel-tanned nappa leather and high-quality vegan materials, ZAQQ barefoot models have a unique appearance. We skillfully play with the two sides of the materials, in combination with the unusual cuts, not only for your feet but also for your eyes, an experience and an absolutely exceptional phenomenon.

construction

Your feet are a miracle of nature and have been perfectly developed over millions of years of evolution. Muscles, bones, joints, fascia and tendons form a complex, interconnected system that is incredibly flexible and sensitive.

Why are we telling you this? Because your new ZAQQ was designed for your feet and your well-being.

A front shoe with a large volume gives your ball of the foot and your toes the space they need to be able to expand in all directions with every step. A completely flat sole with zero heel and no splay keeps your ankles flexible and prevents painful incorrect posture of your entire body. Light cushioning in the sole construction protects your joints and guarantees the incomparable, light ZAQQ running feeling.

Take a closer look at your new ZAQQ barefoot shoes. Do you see how precise the seams are? Inside the shoe you can see the Strobel seam, which connects the bottom of the shoe to the upper. We deliberately did not hide this seam under an inner lining, because perfect craftsmanship should also be shown. Here you can see traditional shoemaking, which makes up the unique charm of every ZAQQ barefoot shoe.

When designing the ZAQQ barefoot shoes, we focused on the essentials. You can tell by the unique and smooth lacing that supports the foot without constricting it, the lack of metal eyelets that spoil the look, a cap at the back that gives the shoe stability and prevents pressure points or blisters when worn, or, for example, a small tab on the back cap that makes it easier to put on.

In a ZAQQ barefoot shoe, no insole* disturbs the comfort. Sweaty feet are a thing of the past, because leather is a natural product, breathes and transports sweat out of the shoe, for a comfortable fit and a healthy foot climate.

As you can see, we have incorporated many ideas and innovations into your new ZAQQ barefoot shoes to give you a special experience - the typical light ZAQQ walking feeling. We also build not only the most beautiful but also one of the lightest barefoot shoes ever. With a weight of around 200 g, you will hardly notice your new ZAQQ barefoot shoes at all.

cutting leather

In our factory we have every opportunity to cut leather and vegan materials to the required size. A distinction is made between hand cutting and machine cutting.

Hand cutting is more interesting from a craftsmanship perspective and is our preferred method. Of course, modern laser cutting tables or water cutting systems can work much more effectively and quickly, but no machine can replace the human eye and decades of experience in working with leather.

That's why when cutting by hand, a template of the required parts is placed on the leather, marked with a leather pen and then cut out with a special knife. The trick is to position the leather and the template in such a way that defects and damage to the leather skin are left out and not processed in the visible area.

In addition, each leather skin has two different directions of tension. This means that depending on the direction in which the leather is cut out, there will be areas on the shoe that can stretch more than others. Your ZAQQ barefoot shoes should, for example, be able to stretch more in width than in length. In addition, the entry should not be too stretchy so that it retains its shape and the shoe still fits perfectly on the foot even after years.

As you can see, it is an art in itself to cut the leather in the right size and shape. Another advantage of hand cutting is that we can build small series for you or develop your individual ZAQQ barefoot shoe.

Afford

It is a common misconception that all people have the same foot shape. Women's feet differ significantly from men's feet in some respects. For example, a woman's foot is proportioned completely differently because women have a narrower heel and a wider forefoot than men. You can easily measure this at home. If you were to simply make a men's shoe smaller and sell it as a women's shoe, it would be a little too narrow in the front area and a little too wide in the heel. In order to make shoes that are really comfortable and fit well, you need different last shapes.

A last is a molded piece made of wood or plastic and is required for the production of a shoe because it replicates the shape of the foot. A shoe model is then ultimately developed based on this mold.

The last is therefore the heart, the soul of every shoe. If the last is not carefully developed and adapted to the foot, then the finished shoe can never be comfortable and fits perfectly.

Almost all manufacturers use a combination last, i.e. a uniform last for men and women, because this is of course much easier to produce and saves a lot of money and time during development. The result, however, is shoes that don't really fit either man or woman and of course have to be "broken in" first, which means that the material has to give in the places where the shoe is tight in order to adapt to the shape of the foot. Tips from the manufacturer such as "stick a plaster on", "wet the shoe" or "a shoe has to be broken in first" are then intended to disguise the poor fit and the manufacturer's profit maximization. In our eyes, quality looks different.

We have therefore taken a lot of time and developed separate lasts for men, women and children. The advantage for you is that your new ZAQQ barefoot shoes do not need to be broken in and fit your foot perfectly straight out of the box, for your well-being and the inimitable ZAQQ walking feeling.

You are welcome to visit us, we will explain the difference and show you our strips. Transparency ensures quality, a principle that we implement every day.

Sew

The leather pieces cut out or punched in the previous step must now be connected to one another in the correct order. The upper part of your new ZAQQ barefoot shoe, also called the shaft, is created by sewing all the individual parts together.

Anyone who has ever tried to sew something knows that this work doesn't happen by itself. To sew the right seam, you need to plan and choose the right materials. To create the perfect seam, you need the right needle, the right thread, the right sewing technique and, of course, the right machine.

Not only do the needle and thread have to be chosen correctly, the way a seam is made also varies greatly. Regardless of whether it is a zigzag seam, a chain seam, a double seam or a decorative seam, our factory has the right and specialized sewing machine for every seam, because only with perfect working conditions can extraordinary products be created.

Strobeln

"Strobeling" is a method of sewing a shoe that is ideal for our flexible ZAQQ barefoot shoes. Unlike other production methods, strobeling does not require the use of joint stiffeners. Another advantage of this method is that there are no bulges, uneven areas or hard edges and the volume of the inner shoe can be used to the maximum.

Ultimately, you will feel this with every step you take with your new ZAQQ barefoot shoes, as this is what gives all ZAQQ barefoot shoes their almost limitless flexibility and comfort.

You can squeeze, twist, turn and crumple your new ZAQQ barefoot shoes as much as you like; thanks to the sophisticated design, your ZAQQ will not mind.

Just take a closer look at your new ZAQQ. Inside you can see the Strobel seam very clearly, which connects the lower part of your barefoot shoe with the upper shaft. Notice how even and accurate this seam is. Here you can see the true craftsmanship of our employees. Why should we hide something so beautiful and high-quality under an insole?

If a shoe literally "fits like a glove", it is often due to its Strobel construction.

The word "strobel" comes from the company that invented this special sewing machine for shoes, the strobel machine. However, you cannot compare a strobel machine with a normal sewing machine, because it works fundamentally differently. A strobel machine connects two parts in a very unusual way. A needle pierces the thread through both pieces of leather. On the other side, a small hook takes the thread and guides it over the edge of the leather back to the front, where the needle catches the thread and pierces the leather again. In this way, loop after loop is strung together until the shoe has been completely circled. In order to strobel a shoe really accurately, a great deal of skill and experience is necessary, because the smooth lower part of the shoe has to be connected to the much larger upper part.

embossing

Barefoot shoes that leave our factory bear the ZAQQ lettering mainly on the insole.

We also use an unusual solution for this lettering. To ensure high-quality workmanship and a special look, these letterings are permanently embossed into the leather or vegan materials using a complex process with a hot stamping stamp.

As the name suggests, a brass stamp is heated to a temperature of exactly 180 ° Celsius and then pressed into the piece of leather using a press. The right pressure and the exact time frame are important to achieve a truly perfect result. The lettering is embossed into the material and retains its shape even after years.

The advantage over transfer stamps or simple color stamps is that the motif cannot be slowly removed by mechanical influences. A shoe that has been embossed with the ZAQQ logo remains a genuine ZAQQ barefoot shoe for its entire life.

As you can see, your new ZAQQ barefoot shoes are really thought through down to the last detail and are truly unique.

Glue and hand-sew the sole*

One of the last and most difficult steps is sewing the sole. There are also highly developed machines for this.

We had to test for a very long time to find the most sustainable and highest quality option.

Sewing the sole also involves many individual, demanding tasks. The shaft must be prepared accordingly at the gluing points. To do this, each shaft is taped by hand with adhesive tape and then the material is carefully roughened. The entire sole is also roughened at the gluing surface in order to create an optimal bond with the adhesive.

The sole is then carefully pulled onto the shaft by hand and placed in the sole press. Here, an air-filled rubber cushion is placed on one side and a ball and heel mold on the other side are placed together under high pressure. This allows the rubber cushion to completely wrap around the sole and glue it precisely.

The right amount is crucial. If too much glue is applied, it will be squeezed out at the edges; if too little glue is used, the sole will not hold properly. If the pressure of the press is set too high, the shaft or the sole can be damaged. As you can see, gluing a sole sounds easier than it really is.

This is also the reason why we spared no expense and effort and decided to have our own factory, because this is the only way we can guarantee that every shoe is made with the same dedication and passion with which we developed it.

After gluing, the ZAQQ sole is sewn. An old shoemaker's saying goes that there is no substitute for a seam other than an even stronger seam. Of course, modern adhesives are able to connect a sole to a shaft. However, there is always the possibility that the adhesive bond will come loose over time in areas that are particularly stressed. Only a seam can provide a permanent solution here. For this reason, a hand-sewn sole represents the highest quality standards and underlines the special nature of your new ZAQQ barefoot shoes. Many manufacturers know this and therefore imitate a seam on their shoes to give customers the impression of higher quality. We at ZAQQ, however, love quality and are not satisfied with half measures.

*except certain models